Materials operating in low-temperature service must retain suitable properties including elongation, yield, and tensile strength and ductility. Element offers a full range of mechanical testing services on advanced materials at cryogenic temperatures to ensure they perform as expected in these extreme conditions.

Different industry sectors are continually exploring new materials with better performing chemical properties and laboratories are challenged to develop new test methods on these demanding materials, which includes testing at very low temperatures.

Testing capabilities as low as 4° Kelvin

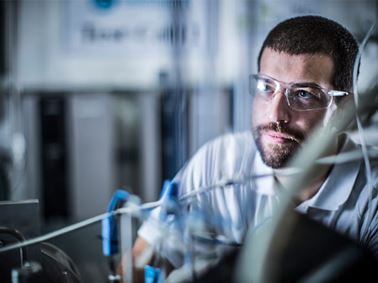

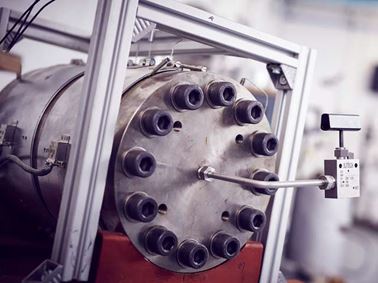

With one of the most comprehensive ranges of materials testing services, we have the experience and expertise in mechanical testing with the use of low cryogenic fluids in providing thermal environments as low as 4° Kelvin (-269 °C/-450 °F). Our state-of-the-art laboratories utilize the latest testing facilities and equipment to carry out cryogenic testing in Helium cooled down to as low as 4.7K and in liquid nitrogen (LN2).

We can evaluate and test such materials as austenitic stainless steels, steel alloys, aluminum alloys, composites, and Al-Li alloys. Using our most advanced computer systems, we are able to monitor control rooms and equipment for seat leakage, temperature, oxygen, and pressure.

Our cryogenic testing services not only assure high performance of your materials but also help you optimize costs, improve operational safety, and reduce environmental impact in even the most challenging operating conditions.

Expertise in many industries

From specimen design and prototyping to test plan development and engineering analysis, Element delivers high quality, reliability, and optimum performance of materials operating in low temperatures to clients from the爱游戏ayx客户端 ,oil & gas, and theenergysector.

One example is the International Thermonuclear Experimental Reactor (ITER) project, where Element has provided mechanical testing services at cryogenic temperature to F4E parts producers for over nine years, including tensile, impact, shear, fracture mechanics, and fatigue growth testing.

Mechanical testing at cryogenic temperatures

As cryogenic testing operations create potentially hazardous test conditions, safety is of paramount importance at all times. Our highly skilled engineers utilize specialist testing areas equipped with the latest in safety protection to eliminate all hazards. We operate our stringent cryogenic testing programs in compliance with health and safety rules, regulations, and industry standards.

Our testing capabilities include:

- Mechanical Fracture Toughness

- Fatigue Testing

- Tensile Testing

- Charpy Impact Testing

- Fatigue Crack Growth Rate (FCGR)

- Surface Crack Tension (SCT)

Element also performsFitness for Service (FFS)和剩余寿命ssessments (RLA) to determine the safety and remaining life of equipment operating at low temperatures. Assessments and studies of this type are frequently used in the Oil & Gas, Power Generation, and Chemical Processing sectors, and on technological plants of hospitals, airports and infrastructures in general. FFS and RLA activities can be applied on theHydrogenemerging sector as well.

For more information about our cryogenic testing services or to request a quote,contact ustoday

More from Element

机械试验ing

Element's mechanical tests show whether a material or part is suitable for its intended mechanical applications.

Temperature and Thermal Testing

Element can recreate the conditions your parts or products will face in actual use.

Hydrogen

Element has decades of experience in testing materials and components for their behavior in hydrogen-containing environments.

Material Behavior at Cryogenic Temperatures

Introduction to relevant physical phenomena and material properties at very low temperatures.